The Importance of an Insert Stiffener

Flexible pipe connections are known for their corrosion resistance, light weight material, and ease of use.

The Importance of an Insert Stiffener

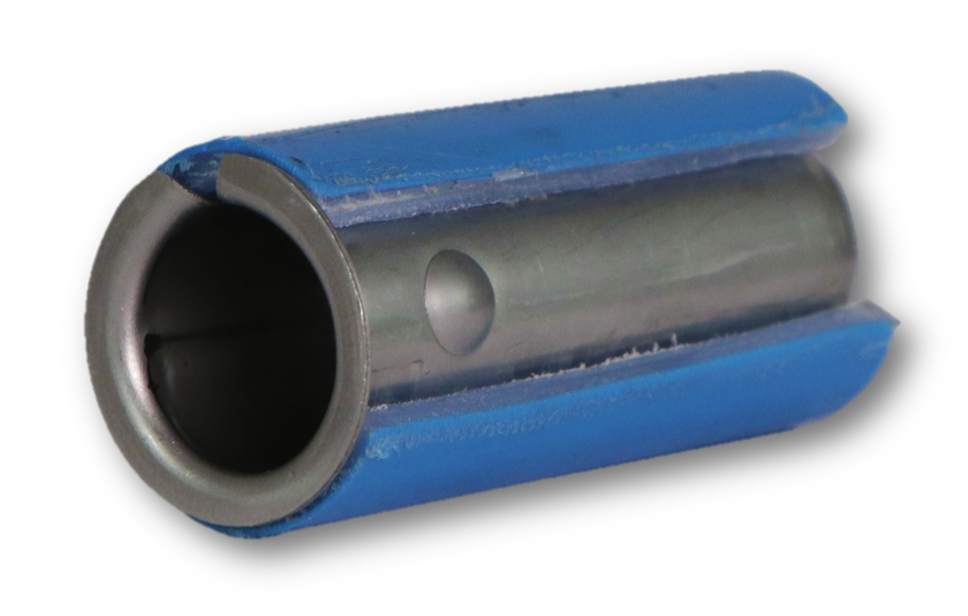

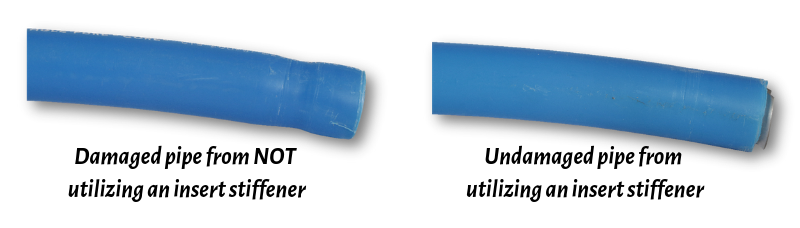

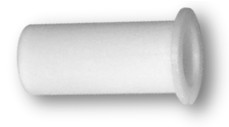

An insert stiffener is designed to support plastic connections such as polyethylene, polybutylene, and PEX piping. When a compression joint is made, the insert stiffener supports 360° around the inside of the tube, offering stability to the tube, leading to a long-lasting watertight seal and pullout strength. When the insert stiffener isn’t utilized on all flexible plastic connections, the plastic will creep away from the joint over time, releasing the pressure, and cause a leak or blow off. See below for visual evidence of what a pipe looks like when an insert stiffener is and isn’t present:

There are three main components to an insert stiffener that allow the accessory to do its job and they include the chamfer, flange, and lay length. Read below for the function and location of each of these components:

|

Name of Component |

Features and Benefits |

Component’s Location |

|

Chamfer |

· Located on the leading edge and allows easier insertion of the stiffener into the poly · Not necessary but recommended for stress relief |

|

|

Flange |

· Located on the opposite end of the chamfer and prevents the user from inserting the insert stiffener too far |

|

|

Lay length |

· Important because different compression joints have different points at which they compress and grip |

|

When choosing the correct insert stiffener for the job at hand, the following factors should be taken into consideration:

- Pipe type: Polyethylene, polybutylene, and PEX piping

- Pipe size: It is recommended to select an insert stiffener that is long enough to support where the fitting contacts the pipe.

- Inside diameter (ID) controlled vs. outside diameter (OD) controlled: ID controlled pipe require the same insert stiffener per size for all Standard Inside Dimension Ratios (SIDRs) while OD controlled pipe requires a specific insert stiffener for each Standard Outside Dimension Ratio (SODR)

**Please consult your insert stiffener manufacturer to ensure the proper insert stiffener is being used.

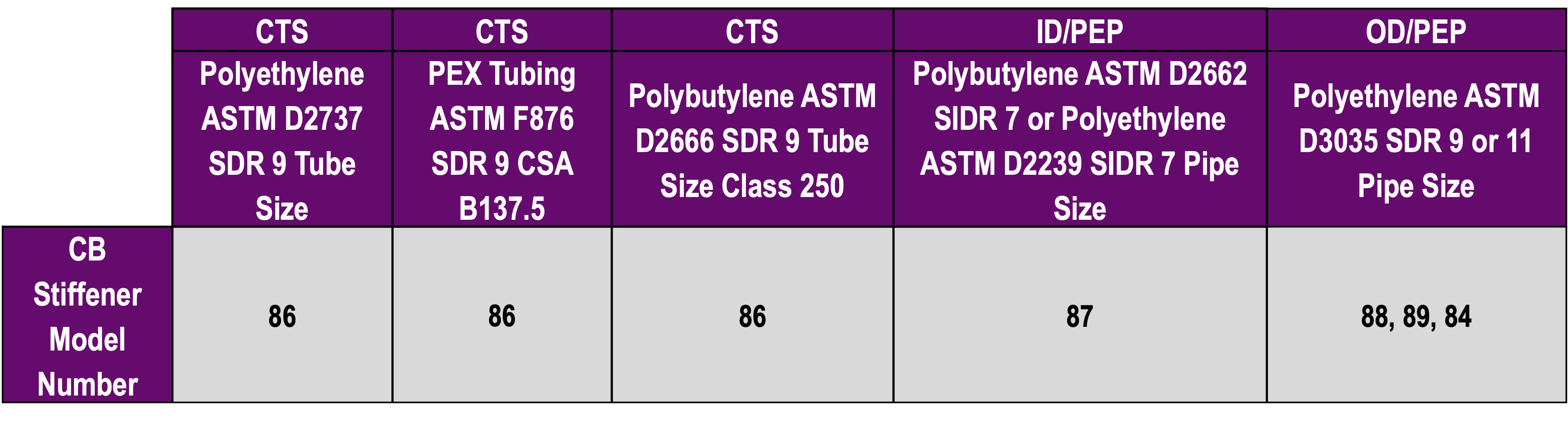

Cambridge Brass offers stainless-steel insert stiffeners that contain a flared end, which prevent the tube from being stabled into the ball of the valve or the stiffener insertion too far into the tubing. These insert stiffeners come with a beveled leading edge for ease of insertion into tubing and reduce stress on the tube when the bending moment is involved. Universal overall length is utilized on all sizes to cover usage on various compression systems within our industry. See below for the types of plastic pipe/tubing for use with Cambridge Brass’ insert stiffener:

The efficiency that insert stiffeners bring to flexible plastic connections help plumbers and utilities make the most of their sought-after qualities. If you’re having trouble deciphering which insert stiffener you should be using, feel free to fill out a contact us form, call our customer service department, or take the ‘Insert Stiffeners’ Cambridge Brass University (CBU) course.